Tavrida Electric, an international circuit breaker and smart switchgear manufacturer

Streamlining operations management and finance using 1C:ERP.

“The implementation of the 1C:ERP in our Canadian division was a benchmark project for us, as we wanted to choose the best solution to roll-out in our divisions requiring an ERP in other countries.

As a result, we have seen that the solution perfectly fits our business profile, helps in cost controlling, and increases the efficiency in our core business processes.”

Customer: Tavrida Electric, vacuum switching equipment, and smart switchgear manufacturer

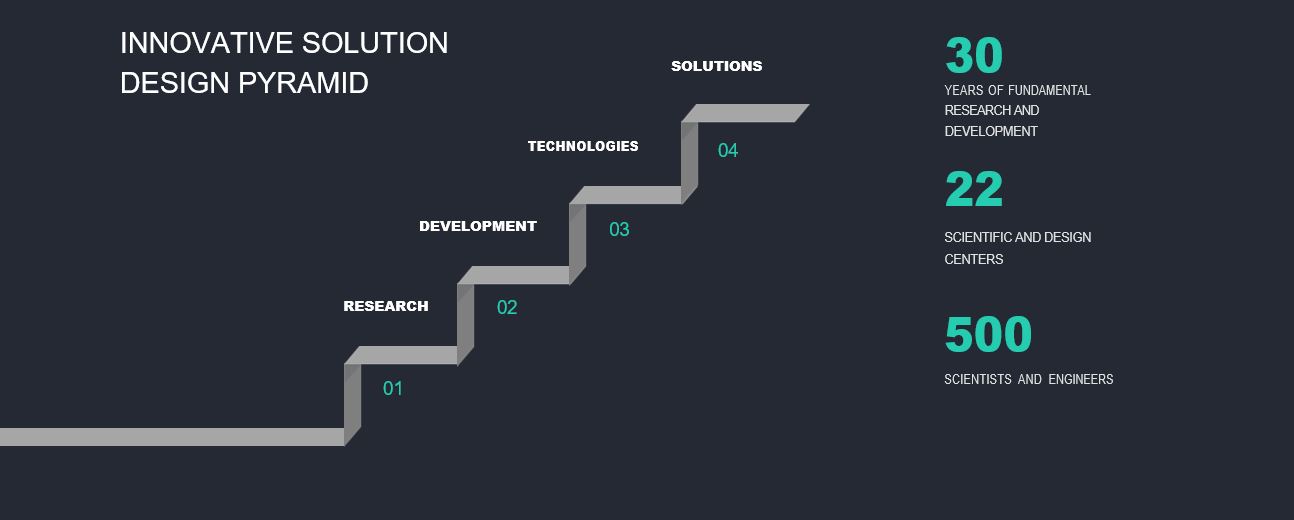

Tavrida Electric is an international group of companies that develops and manufactures a range of innovative vacuum switching equipment and smart switchgear solutions for indoor and outdoor applications.

It is one of the three most massive circuit breakers and recloser suppliers in the world. There are more than 70 divisions in 22 countries, employing nearly 3000 people. The implementation project took part in the Canadian division of Tavrida Electric.

The whole project of the 1C:ERP implementation took around 12 months. Sixteen employees are working with the system in the company's office in Delta, British Columbia.

During the project, the following functional blocks were implemented:

- Sales

- Warehouse management

- Procurement

- Production planning

- Management accounting

- Financial accounting and Cash management.

Challenges: Lack of automation and planning capabilities, ineffective inventory management

Tavrida Electric struggled with the effective integration of core business processes and scalability of complex IT landscape consisting of QuickBooks, Microsoft Dynamics, and other solutions. These tools could not be used for combining needed reports, and there also were reliability issues.

As a result, the management at global headquarters could not fully trust the collected data and make data-driven decisions. So, the company had to consider another ERP system.

The new solution should be able to solve the main business challenges:

- to boost the flexibility of financial accounting for better regulatory compliance.

- to develop unified reporting forms and automated data consolidation.

- to implement a shared accounting service center with centralized database.

- to eliminate manual labor.

- to provide flexible planning opportunities.

- to classify all the goods and product master data and item classifiers.

Results

The 1C:ERP solution was chosen for its flexibility, reliability, and customization features that allows designing of custom reports and forms. The implementation of 1C:ERP allowed the management team of a global headquarters to access reliable data about the Canadian business unit.

This resulted in increased efficiency of reporting, planning, and control, as well as reduced costs for the business.

The main results of the project were:

- Increased efficiency of financial reporting.

- Higher quality of the data used by managers in the decision-making process.

- Better control of the KPIs and other business-critical information of the Canadian division.

- Acceleration of reporting and planning that results in decreased costs of product delivery.

- Reduced costs of materials delivery due to more efficient inventory management.

- The system demonstrates a high level of reliability and stability.